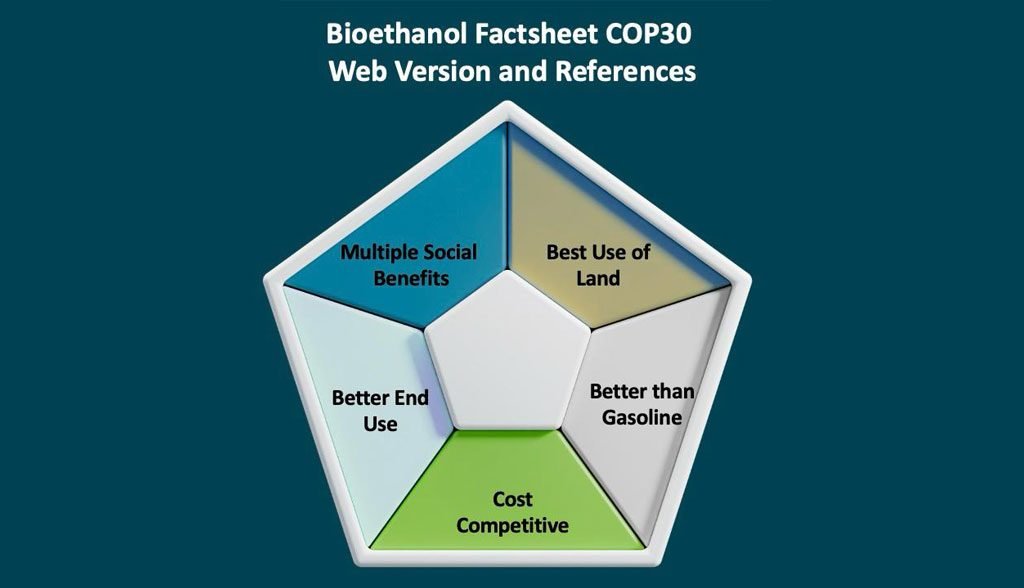

Launched at COP30 in Belém, this Factsheet authored by Glaucia Mendes Souza (University of São Paulo), Luiz Augusto Horta Nogueira (Federal University of Itajubá), and Raffaella Rossetto (Agronomical Institute of Campinas), presents a comprehensive overview of bioethanol’s role in global climate change mitigation.

The Factsheet compiles scientific data and evidence showing how ethanol — produced from sugarcane, corn, and other biomass — has been reducing emissions, creating jobs, and driving the energy transition in more than 50 countries.

It also highlights Brazil’s leadership with its 30% ethanol–gasoline blend (E30) and India’s rapid progress, achieving a 20% (E20) blend in 2025.

The bioethanol contribution to the global climate change mitigation effort

Glaucia Mendes Souza (University of São Paulo), Luiz Augusto Horta Nogueira (Federal University of Itajubá) and Raffaella Rossetto (Agronomical Institute of Campinas)

Factsheet

Web version with references

1. Global Role of Biofuels in Climate Change Mitigation

Historically, biofuels have been the most effective in reducing oil demand. According to IEA studies, emerging economies are rapidly increasing their biofuel usage. In the United States, Europe, and China, the use of renewable electricity in transportation is expected to grow. However, in many other parts of the world, biofuels continue to be the main option for decarbonization, representing nearly 90% of the avoided oil demand by 2028. Globally, biofuel production has surged by 50% over the past decade.1

2. Strategic Role of Ethanol in Decarbonizing Transport

Ethanol plays a strategic role in the decarbonization of transportation. As a major conventional biofuel, ethanol is commercially available, economically competitive, scalable, and can be immediately used in existing transport infrastructure. Both sugar cane and corn-based ethanol, along with biodiesel, are being sustainably produced and commercialized in significant quantities across several countries. These biofuels are currently the most relevant alternatives to fossil fuels globally. Over time, there have been improvements in yields, costs, and environmental indicators. Biofuel blending mandates and effective public policies have been crucial in supporting implementation and technological advancements.2

3. Meeting Net Zero Targets Through Biofuel Expansion

To meet the IEA’s Net Zero scenario, biofuel consumption needs to increase by 2.5 times by 2030, which would offset approximately 800 million tons of CO₂, or about 10% of current transport emissions. In the shipping and aviation sectors, biofuels, including ethanol, must rise from less than 1% currently to around 15% by 2030 and 80% by 2050. A total of 57 countries have implemented bioethanol use requirements through blending mandates. Brazil and Paraguay lead the way with a gasoline-bioethanol blend requirement of 30%. India, which has recently started blending bioethanol and achieved its average ethanol blending target of 12% in 2023, demonstrates the rapid success of this approach reaching 20% in 2025. Belém 4x Pledge on Sustainable Fuels, to be endorsed during the COP30 Belém Climate Summit, seeks countries to commit their intent to work collaboratively and expeditiously to pursue the expansion of sustainable fuels use globally by at least FOUR times by 2035 from 2024 levels, taking into consideration different starting points and national circumstances. This pledge is supported by an IEA report on Delivering Sustainable Fuels Pathways to 2035 that states that If fully legislated and implemented, current and proposed national and international policies would put the use of sustainable liquid and gaseous fuels on a path to nearly double from 2024 levels by 2030 and quadruple by 2035.3

4. Ethanol as Fuel History

Internal combustion engines (ICEs) dominate the worldwide vehicle fleet, accounting for over 95% of total road transport energy demand. Bioethanol, produced from renewable feedstocks, offers a versatile and immediate pathway for reducing dependence on petroleum-based fuels while lowering greenhouse gas (GHG) emissions. Its widespread adoption in both low-level blends and pure forms demonstrates that ethanol is not only an alternative but also a complementary fuel that can operate across a broad range of propulsion technologies.

5. In Brazil, ethanol’s trajectory diverged from global trends

Initial experiments with alcohol-fuelled vehicles date back to the 1920s, with engines adapted to burn pure ethanol and blends developed such as USGA (a mixture of ethanol, ether, and castor oil). In 1931 (Decree 19.717), the 5% ethanol blend in gasoline was established, making Brazil the first country to establish compulsory use of bioethanol in road transport.

6. Oil crises of the 1970s and onwards until now

Brazil’s Programa Nacional do Álcool (Proálcool), launched in 1975, aimed to replace costly petroleum imports with domestically produced sugarcane ethanol. The program triggered technological innovations in both the sugar industry and the automotive sector, such as the flex-fuel engine, launched in 2003, able to use efficiently any blend of gasoline and hydrous ethanol, a technology very well received by the market, representing more than 90% of new cars sales. By the late 1970s and 1980s, millions of vehicles were running on higher ethanol gasoline blends and pure hydrous ethanol (E100), supported by a nationwide distribution infrastructure. Ethanol use in Brazil never receded; the ethanol content has evolved during the last decades. In 2025, a mandatory 30% blend (E30) and a fleet of over 37 million flex-fuel vehicles make Brazil the global benchmark for large-scale ethanol adoption, where the consumption of this biofuel, circa 31 billion litres in 2024, represented a volume comparable to the gasoline consumption.

7. Global Sugarcane and Bioethanol Production Landscape

Sugarcane is cultivated in >100 countries: ~20 countries account for >80% of global sugarcane sugar. Global bioethanol production: ~117 billion liters, ~30–35% of sugarcane from Brazil, India, Thailand, Colombia, Paraguay. Blending mandates in 57 countries: typically 5%–30%, Paraguay 30%, Brazil 30%, India 20%. Sugar Brazil (#1), Mexico, Colombia, Argentina, Guatemala, Peru, Paraguay, Costa Rica Brazil the largest with >40 Mt. Ethanol ~40 billion (36 billion from Brazil). Blending mandates: 2-30%; Brazil and Paraguay 30%. Sugar: India, Thailand (#2 and #3), Philippines, China, Pakistan, Vietnam, Myanmar. Ethanol ~5–6 billion L/year in India, ramping up; Thailand, Philippines: ~1–2 billion L each. Blending mandates India (20%), Thailand, Philippines (10%), China (10% in 9 provinces), Japan (~3%). Sugar South Africa, Sudan, Ethiopia, Kenya, Malawi, Mozambique, Egypt. Ethanol Malawi, Mozambique, South Africa, Ethiopia, Kenya, Sudan <1 billion L/year combined. Blending mandates 5-10%. Sugar Australia (#10), ~4–5 Mt sugar); Fiji also small-scale producer. Ethanol Queensland ~0.3–0.5 billion L/year). Blending mandates New South Wales, 4%). Sugar Small, from overseas territories. Ethanol Minimal imports from Brazil. Blending mandates EU average ~6.4%, E10 France, Germany, Spain, Sweden, UK, Norway (24.5%), Netherlands (18.9%), Finland (13.5%).4

8. Biofuels Policy Agenda in Emerging Markets

Biofuels policy agenda in emerging markets has been evaluated and classified according to its implementation stages.5 In the Americas blending mandates have been fully implemented in Argentina, Brazil, Bolivia, Colombia, Ecuador, Peru, Paraguay, Uruguay. A policy framework is in place but not implemented in Costa Rica, Guatemala and Mexico. In Asia blending mandates have been fully implemented in Indonesia, Malaysia, India, Thailand, Philippines, China, Pakistan, Vietnam and Myanmar. Blending mandates are partially implemented in China, Japan and South Korea. A policy framework is in place but not implemented in Nepal and Pakistan. In Africa blending mandates are fully implemented in Malawi. Blending mandates are partially implemented in Ethiopia and Zimbabwe. A policy framework is in place but not implemented in Angola, Cote d’Ivoire, Kenya, Mozambique, Nigeria, South Africa and Uganda.

9. GHG Emission Reductions from Brazilian Ethanol

Ethanol produced from sugarcane and second-crop corn in Brazil can lower greenhouse gas emissions by 75-85% compared to gasoline. With advancements in technology, both first-generation (1G) and second-generation (2G) ethanol have the potential to achieve near-zero or even negative carbon intensity, particularly when combined with Bioenergy with Carbon Capture and Storage (BECCS) (Bioenergy with Carbon Capture and Storage).6

10. Country Success Cases: Brazil, USA, and India

Three success cases exemplify how bioethanol programs can be succesful as country strategy for decarbonization.7 The Brazilian production model: E30 baseline + widespread FFVs and E100 use, growing hybrid‑FFV options. RenovaBio/CBIOs, certification, Agro‑industrial integration. 2024 Ethanol Production: Brazil produced a record 36.83 billion liters of ethanol in 2024, with corn-based ethanol rising 32.8% to 7.7 billion liters. The USA production model: E10 nationwide baseline, E15 expanding, E85 for FFVs. RFS + state LCFS programs; legacy FFV fleet and blender pump network. 2024 Ethanol Production: EIA expects fuel ethanol output at ~1.05 million barrels/day in 2024 and 2025. Ethanol Exports: U.S. ethanol exports rose by 37% in 2024 compared to 2023. The Indian production model: rapidly rising blend levels, E20 target, OMC procurement, and OEMs validating E20/flex‑fuel engines. Blending Targets & Progress: Blending reached 15% in 2023–24, target is E20 by 2025. Current Blending Rate: Ethanol blending rose to 16.23% by Dec 29, 2024, and 19.6% in January 2025.

11. Brazil’s Contribution to Transportation Decarbonization

The Brazilian contribution to decarbonization of transportation. Largely renewable internal energy offer (50%) with 16.7% derived from sugarcane and 16.6% from other biomass sources. Electricity is 88.2% renewable. Transportation is 25.7% renewable 37.3 Billion L/yr of ethanol. 9.2 Billion L/yr of biodiesel. 424 biofuel plants. From 1975 to 2024 Brazil consumed 888 Billion L of ethanol displacing 1.4 Billion ton CO2eq. 85% of the fleet is flex. “Fuel of the Future” legislation. Current target is 705 Mt CO2 eq by 2037 of avoided emissions. Currently E30 and B15 (B20 by 2030).8

12. Co-Products and Integrated Production Systems

Food, feed, fuels, and power are produced simultaneously. Ethanol is manufactured year-round, generating various co-products such as sugar, DDGS for animal feed, oil, bioethanol, and bioelectricity. All residues are completely recycled. By integrating sugarcane and corn ethanol production, output can be increased while further reducing emissions.9

13. Main Feedstocks: Sugarcane and Second-Crop Corn

In Brazil, sugarcane is the primary feedstock for ethanol production, with integrated processes yielding sugar, ethanol, molasses, yeast, spirits, animal feed, and cellulose. Second-crop corn is cultivated after corn or soybeans, utilizing existing agricultural land and posing a low ILUC risk, which enhances efficient land use. The evidence suggests that biofuels positively impact food security, demonstrating that biofuels and food production are not mutually exclusive. Sugarcane and corn complement each other well, enabling year-round production. The development of biofuels has improved agricultural infrastructure, and biofuels are seamlessly integrated into our food production system. As biofuel production has increased, so has the production of agricultural commodities.10

14. Land Use Efficiency and Potential for Expansion

There is no necessity to utilize native vegetation land to meet Brazil’s additional volume needs by 2035. In a conservative scenario, 20 billion liters can be produced using spare land. An additional 10 billion liters could be achieved by enhancing yields. From 1975 to 2023, soybean yields increased by 101%, corn yields by 265%, and sugarcane yields by 85.6%. If 28-34 million hectares (30%) of the 177 million hectares of pastureland were converted to agricultural land, and 12 million hectares (6%) were allocated for bioenergy crops, an extra 8 billion liters of biofuels could be produced. Utilizing all second crop corn for ethanol could yield an additional 6 billion liters, as currently only 15% is used. In Brazil, sugarcane can realistically achieve yields of 120–150 tons per hectare, while maize can reach 9–15 tons per hectare, depending on whether the systems are rainfed or irrigated. Both crops have a yield gap of approximately 40–50% compared to their potential, indicating significant opportunities for improvement through better irrigation, soil fertility, and management practices.11

15. Pasture Intensification and Soil Recovery Benefits

As Brazil emerged as the leading exporter of food commodities, biofuels experienced growth. This expansion was facilitated by pasture intensification, which freed up land, and the introduction of second cropping. In Brazil, the growth of energy crops was primarily associated with converting degraded lands and pastures, offering the additional benefits of soil recovery and carbon sequestration.

16. Brazil’s Land Use Profile and Conservation Policies

Brazil maintains 66% of its land covered with native vegetation. Agriculture accounts for 8%, pastures for 21%, and urban areas for 4%. The country spans 850 million hectares, with approximately 66% of this area covered by forests. Integral conservation units and indigenous lands cover 200 million hectares, which is 23% of the total territory. Around 49% of rural properties are covered with native vegetation, constituting 33% of Brazil’s land. Brazilian rural producers are required to preserve or recover at least 20% of their land with native vegetation. This preservation requirement is increased by mandatory conservation on riverbanks and hilltops and can be further expanded in priority conservation areas. Near the Amazon, the minimum preservation requirement is 80%.12

17. Yield Growth, Efficiency Gains, and Land Footprint

Crop yields and land availability have both increased. Since 1985, the area dedicated to sugarcane has grown by 1.5 times, stalk yield has increased by 1.8 times, and the production of ethanol, sugar, and bioelectricity has risen by 5 times. These improvements are attributed to advancements in crop breeding, better management practices, and increased industrial efficiency. The land footprint of ethanol production, which includes both sugarcane and corn, occupies less than 1% of Brazil’s territory. Over the past 20 years, approximately 98% of sugarcane expansion has taken place on degraded pastures or agricultural lands rather than forests. Second-crop corn ethanol utilizes about 0.5% of agricultural land. Additionally, the introduction of second and third-crop corn has been implemented. Co-benefits include enhanced soil fertility, reduced fertilizer requirements, and increased biodiversity through crop rotation practices such as soy/peanut → sugarcane → corn.13

18. Food & Biofuels Debate and Food Security Impacts

The impact of bioenergy derived from edible versus non-edible feedstocks on food availability, prices, and production has been studied extensively. Two-thirds of the articles indicate either positive effects or no impact on food availability, with bioenergy showing beneficial outcomes at the household level. Regarding food prices, negative effects were primarily observed in countries with a high Social Development Index (SDI), accounting for three-quarters of such cases. In terms of food production, bioenergy positively influences production in low SDI countries, particularly in the Global South, and at the household level. However, in these low SDI countries, bioenergy does not affect food prices. Negative effects are more frequently reported in studies based on modeling, whereas observed data tends to report fewer negative impacts. A total of 224 papers were reviewed, and no correlation was found between the type of bioenergy feedstock (edible, non-edible, or a combination) and food security.14

19. Positive Contributions of Bioenergy to Food Security

Observed improvements brought by bioenergy that contribute to food security include agricultural infrastructure, purchasing power, energy access, agriculture modernization and soil quality.15

20. Socio-Economic Impacts of Sugarcane Sector

Improved socio-economic indicators. Improved Social and Economic Impacts. Improved purchasing power. Jobs – In 2023, sugarcane sector employed 2.2 million people (direct + indirect), including 70,000 small producers. Formal employment in sugarcane: 87% vs. 34% in general agriculture. Average wage 46% higher in sugarcane sector. Local development – New mills increase municipal GDP per capita by ~$1,000/year for at least 10 years. Energy access – Rural electrification through sugarcane bioelectricity correlates with higher Human Development Index.16

21. Best Management Practices for Sustainable Biofuels

Best Management Practices are implemented to promote sustainable biofuels production, enhancing its social, environmental, and economic benefits. Adhering to labor laws in the agricultural sector ensures fair, safe, and ethical working conditions, thereby improving its social impact. Compliance with State and National Environmental Regulations helps integrate various ecosystem services into resource management, significantly boosting its environmental performance indicators. It is recommended to provide proper training and continuous professional development for farm workers, adopt safer practices, utilize technology more effectively, and enhance productivity throughout the agroindustrial system.

22. Agronomic Practices in Sustainable Sugarcane Production

Sustainable sugarcane production involves several agronomic practices that enhance efficiency and environmental benefits.

- Soil Preparation: Planting in beds with no-till or minimum-till methods helps reduce greenhouse gas emissions. GPS technology aids in traffic control, preventing soil compaction.

- Biofuels: Utilizing biofuels in farm equipment lowers carbon emissions.

- Straw Layer: A straw layer of 4 to 10 tons (dry matter) per year protects the soil from erosion, retains moisture, and recycles nutrients.

- Soil Amendments: Lime and gypsum are applied only in beds or rows to address soil constraints, allowing roots to grow deeper and access more water and nutrients.

- Crop Rotation: Growing soybeans, peanuts, and green manure in sugarcane replanting areas reduces the need for nitrogen fertilizers, enhances biodiversity, protects against soil erosion, and adds organic matter and nutrients. Corn planted for ethanol production in these areas optimizes land and equipment use, boosting ethanol output. The protein-rich byproduct, DDG, and corn oil are integrated from various production chains.

- New Varieties: Three breeding programs and one for energy cane focus on developing more adapted, productive, pest-resistant, disease-resistant, and drought-tolerant varieties.

- Biological Control: Pests such as Diatraea saccharalis, Mahanarva fimbriolata, and Sphenophorus laevis are managed through biological control methods.

- Weed Control: Herbicides applied by drones offer greater accuracy and reduce the amount of product used.

- Irrigation: Precision water management tools enhance water use efficiency, minimize waste, and enable recycling opportunities.17

23. Fertilization, Residue Use and Recycling

- Fertilization: adoption of low C fertilizer sources, balanced nutrient doses, organomineral fertilizers, compost, livestock manure.

- Residue use: organic residues are used instead of mineral fertilizers. Filter cake is composted to mineralize nutrientes. All residues produced in the sector are used to grow sugarcane.

- Vinasse recycling: micronutrientes (mainly K and S, some N, Ca, P). Substitutes for K fertilizer. Vinasse mixed with other nutrients is applied in the rows, providing all the nutrients needed in one operation.

- Biodigestion: filter cake and vinasse can be biodigested to produce energy without losses of nutrientes.

- Biofertilizers and bioinputs: (hormones, amino acids) enhance sugarcane metabolic efficency, foster improved interactions among microrganisms (soil and plant) leading to greater nutriente uptake, increased biomass production and higher sugar content.

- Precision agriculture: new machines and the integration of new sensors into planters, harversters, and other agricultural equipment enhances machine efficiency, minimizes soil compaction and crop row trampling and reduces fuel comsuption.

- Forest and green area preservation: legislation in effect, sugarcane properties must maintain 20% of the area as forests and riparian regions (20 to 50m).18

24. Emissions Reduction Through Crop Rotation and Bioinputs

Biofuel crops produced in Brazil have significantly low emissions, partly because they need less fertilizers, a major contributor to emissions. In areas where sugarcane fields are being reformed, sugarcane production is alternated with the cultivation of peanuts and soybeans. Similarly, corn is alternated with soybeans. This dual planting system leverages the nitrogen-fixing ability of legume species like soy and peanuts, which enriches the soil with nitrogen and minimizes the need for fertilization. Using such practices biofuels can reduce emissions by up to 85% when replacing gasoline and diesel. For Brazilian corn ethanol, the carbon intensity can be nearly zero or even negative.19

25. Carbon Sequestration and Atmospheric CO₂ Removal

Bioenergy has positively impacted food security by improving soil quality through land restoration and increased soil carbon. Over the past 20 years, 98% of sugarcane expansion has taken place primarily on degraded pastures and agricultural lands.20

26. Renovabio: Brazil’s Transportation Decarbonization Framework

Sugarcane cultivated in Brazil removed 9.8 MtCO2/year from the atmosphere. In 20 years this is equivalent to planting 1.4 billion trees. This amount is equivalent to reforesting 1 million football fields.

Renovabio consists of three main components: Decarbonization Targets, Certification of Production, and Decarbonization Credits. The national goal for reducing emissions over the decade is 620 MtCO2eq, which is divided into specific targets for fuel distributors based on their fossil fuel market share from the previous year. The Certification of Production involves a life cycle analysis that evaluates producers’ efficiency by calculating net emissions per unit of energy. Decarbonization Credits (CBIOs) are issued to producers and traded on the stock exchange market, where distributors purchase them. Compliance with the targets is demonstrated by the retirement of CBIOs.

27. Emerging Markets Potential for GHG Mitigation

The potential of emerging markets to help increase biofuel production by 2.5 times by 2030, thereby displacing nearly 800 million tons of fossil CO₂ or 10% of current global transport emissions, has been examined.21 A total of 45.7 billion liters of biodiesel and 64.7 billion liters of ethanol could be produced using pastureland, ranging from 0.1% to 10.7%. Life Cycle Assessment (LCA) analysis estimates potential greenhouse gas (GHG) savings of over 300 million tons of CO2 equivalent per year. Developing countries with large populations and high energy demands, such as Argentina, Brazil, China, Colombia, Ethiopia, Guatemala, India, Indonesia, Malaysia, South Africa, and Thailand, were evaluated. Collectively, these countries account for 47.0% of the global population and 27.0% of CO2 emissions from the transportation sector. If these emerging economies were to match the per capita carbon intensity of the transportation sector as seen in OECD countries, global transportation sector emissions would more than double.22

28. Multiple studies highlight ethanol’s competitive performance relative to electric vehicles (EVs)

No single “best” technology exists globally; suitability depends on local conditions, infrastructure, and energy mix. Hybrids with biofuels are a robust solution for many countries, balancing decarbonization with practical considerations like resource use. EVs may be optimal where grids are clean and long vehicle lifetimes dilute battery-related emissions. Biofuels remain essential for near-term decarbonization, particularly in regions with existing ethanol infrastructure. ILUC should not be included in carbon accounting, as it introduces uncertainty and biases against biofuels. Policymakers must ensure clarity in assumptions and criteria, avoiding analyses driven more by geopolitical or economic interests than technical accuracy.23

29. There are several cases of success with bioethanol being adopted in large scale.

Brazilian production model adopted in 2025 a E30 baseline. It has widespread use of Flex-Fuel Vehicles and E100 use, growing hybrid‑FFV options. RenovaBio is the policy framework and CBIOs the decarbonization credits awarded to producers after certification. It shows a strong enphasis on agro‑industrial integration. In 2024 Brazil produced a record 36.83 billion liters of ethanol in 2024, with corn-based ethanol rising 32.8% to 7.7 billion liters.

The Indian production model showed rapidly rising blend levels with a E20 target, OMC procurement, and OEMs validating E20/flex‑fuel engines. Blending reached 15% in 2023–24 with 707.4 crore liters of ethanol; target is E20 by 2025. Ethanol blending rose to 16.23% by Dec 29, 2024, and 19.6% in January 2025.

The USA production model poses an E10 nationwide baseline, E15 expanding, E85 for FFVs; RFS + state LCFS programs; legacy FFV fleet and blender pump network.

The 2024 EIA forecast expects fuel ethanol output at ~1.05 million barrels/day in 2024 and 2025. U.S. ethanol plant capacity increased ~2% between Jan 2023– Jan 2024, with major capacity in Midwestern states. U.S. ethanol exports rose by 37% in 2024 compared to 2023.24

30. Ethanol as a transport fuel: better than gasoline in many important aspects

Ethanol’s advantages as a transport fuel derive from its distinctive physical and chemical properties. Its high oxygen content (~35% by mass) improves combustion efficiency, reduces carbon monoxide emissions, and contributes to higher octane ratings compared with conventional gasoline. This renewable fuel is actually better than gasoline in many important aspects.

Higher Octane Rating and Sensitivity

Ethanol possesses high Research Octane Number (RON ~108) and Motor Octane Number (MON ~89), making it suitable for high-compression engines. This property allows for improved thermal efficiency and enables modern engine technologies such as turbocharging and direct injection. The recent rise of the minimum RON octane rating of Brazilian gasoline to 94 in 2025 was induced by the mandatory blending of 30% anhydrous ethanol (E30), adopted in August 2025. The U.S. Department of Energy’s Co-Optima project identified ethanol’s high “sensitivity” (parameter given by the difference between fuel octane number measured by two methods, Motor and Research) as a relevant characteristic for next-generation high-efficiency engines.

Proper Fuel Volatility and Driveability

Blends with ethanol alter vapour pressure and cold-start performance, and can accomplish required specification by adjusting the base gasoline adopted. In tropical climates such as Brazil, driveability challenges are minimal, but under very low temperatures, the adoption of E85, a blend which maintain 15% gasoline, improves engines cold-start behaviour.

No Problems with Phase Separation and Material Compatibility

Ethanol is able to dilute well with either gasoline or water, thus reducing the risk of phase separation in blends. In fact, these blends are widely stable, without records of phase separation problems, even after decades of adoption. Regarding materials, since the 70’s vehicles have been designed with compatible elastomers and metals.

31. Lower Emissions Profile

When blended into gasoline, ethanol reduces significantly particulate matter and carbon monoxide in the combustion products. Regarding aldehyde emissions, it is worth noting that emissions from ethanol combustion are mainly formed by acetaldehyde, a type of aldehyde that is far less aggressive and better tolerated than formaldehyde, a toxic compound. Studies and years of monitoring in several Brazilian cities confirm net reductions in toxic emissions and enhanced urban air quality when ethanol replaces gasoline.

32. Bioethanol fuel properties

Proper Fuel Volatility and Driveability

Blends with ethanol alter vapour pressure and cold-start performance, and can accomplish required specification by adjusting the base gasoline adopted. In tropical climates such as Brazil, driveability challenges are minimal, but under very low temperatures, the adoption of E85, a blend which maintain 15% gasoline, improves engines cold-start behaviour.

No Problems with Phase Separation and Material Compatibility

Ethanol is able to dilute well with either gasoline or water, thus reducing the risk of phase separation in blends. In fact, these blends are widely stable, without records of phase separation problems, even after decades of adoption. Regarding materials, since the 70’s vehicles have been designed with compatible elastomers and metals.

Ethanol Impacts on Engine Performance and Efficiency

The good properties of ethanol as a fuel allow for significant gains in performance and efficiency in combustion engines, an effect proportional to the increase in ethanol content in a mixture with gasoline up to the use of pure hydrated ethanol.

High Compression Ratios and Efficiency

Because of its high-octane rating, ethanol supports higher compression ratios than gasoline, directly improving brake thermal efficiency. Laboratory tests show that ethanol-fuelled engines can achieve efficiencies above 40%, largely surpassing typical gasoline benchmarks.

Low Air/Fuel ratio and High Torque

Even though it has a lower calorific value than gasoline, ethanol requires around 40% less combustion air, which makes it possible to inject more energy into the combustion chamber, resulting in higher torque and more power at a given rotation speed.

Flexible-Fuel Vehicles (FFVs)

With the development of modern combustion systems from 2000 onward, featuring fuel injectors and oxygen sensors, carburetors were superseded, allowing engines to run on any blend of ethanol and gasoline with excellent performance. Currently, most motorcycles sold in Brazil use flex-fuel engines. Honda reports having sold over 8 million FFV motorcycles in Brazil and is beginning to expand its market for these models in India.

Hybridization and Advanced Engines

Ethanol’s properties align with emerging trends in hybrid vehicles. The engines in these vehicles use the Atkinson Cycle, an improvement on the traditional Otto Cycle, which, when optimized for ethanol use, achieves efficiencies close to 41%. More efficient and less polluting engines maximize the advantages of electric drive, such as high starting torque, which eliminates the need for gearboxes, and regenerative braking, which contributes to fuel economy, especially in urban areas.

Ethanol-powered hybrids, the bioelectric vehicles, emit only 77.5 gCO2e/km, combining the cleanest fuel with the most efficient powertrain.

A drive with HEV100 takes 12.9 km to emit 1 kg of CO2eq, while a ICEV takes 3.7 km.25

33. Emerging Technologies

Ethanol’s versatility extends beyond road transport. Brazil’s agricultural aviation sector has long used the Embraer Ipanema EMB-202, the world’s first series-production aircraft certified for pure ethanol. Over 1,500 units are in operation, demonstrating ethanol’s safety and viability in aviation. Finally, ethanol emerges as well as a strategic input for sustainable aviation fuel (SAF) via alcohol-to-jet (ATJ) pathways, and for maritime applications under development. Fuel-cell research is also advancing, with ethanol reforming for hydrogen production to be used in solid oxide fuel cells (SOFCs).

34. Bioenergy and the Sustainable Development Goals

Bioenergy, among renewable energy options, has the most extensive societal impacts and contributes significantly to many Sustainable Development Goals. A recent AI study analyzed 11,439 publications to define the roles of biofuels, biomass, and bioenergy in achieving these goals.26

The authors identified the impacts of biofuels on all Sustainable Development Goals (SDGs), with the most significant effects on SDGs 7, 13, 12, 9, 15, 8, 2, and 11. This large set of studies evidenced the following aspects:

- SDG 7 – Affordable and Clean Energy: Bioenergy development significantly increases the share of renewables in the energy mix, playing a crucial role in the global energy transition. Biofuels offer renewable, high-energy-density alternatives to fossil fuels, particularly in transportation.

- SDG 13 – Climate Action: Biofuels and biomass are vital for greenhouse gas mitigation. Life cycle analyses show their potential to reduce emissions throughout supply chains, while advanced management practices minimize land use.

- SDG 12 – Responsible Consumption and Production: Biofuels align with circular economy principles by transforming agricultural residues, municipal waste, and other biomass into energy and bioproducts. Innovations in supply chain optimization and biorefinery integration reduce environmental impacts, promoting resource efficiency and waste reduction.

- SDG 9 – Industry, Innovation and Infrastructure: Bioenergy drives systemic innovation in conversion technologies, supply chains, and industrial scaling. Research emphasizes the need to upgrade infrastructure with clean technologies and strengthen scientific and industrial capacities. Investments in biorefineries, transport networks, and pipelines, especially in Brazil, Argentina, and India, illustrate how infrastructure supports biofuel scaling and competitiveness.

- SDG 15 – Life on Land: Sustainable biomass cultivation can boost land productivity, enhance resilience to climate variability, and restore degraded areas, ensuring biofuel expansion does not harm biodiversity and ecosystem services.

- SDG 8 – Decent Work and Economic Growth: Biofuels contribute to economic growth and job creation, especially in rural areas, by bridging yield gaps and enhancing productivity through technological advancements. They serve as engines of employment and inclusive growth, particularly in developing countries.

- SDG 2 – Zero Hunger: Although only 14.2% of studies link bioenergy to SDG 2, its impact is significant. Modern agricultural practices balance food and fuel production, supporting resilient agricultural systems that enhance food security while enabling energy production.

- SDG 11 – Sustainable Cities and Communities: Bioenergy is increasingly integrated into urban sustainability plans, aiding in low-carbon transport and decentralized energy supply. This helps cities reduce their environmental footprint, pollution, and meet climate targets.

35. Policy, Technology, and Social Acceptance Enablers

Adoption of biofuels is enabled by subsidies, incentives, regulations, and policy-integrated life cycle analysis. Notable examples of such policies include Brazil’s Proalcool Program, Renovabio, California’s LCFS, India’s Ethanol Blending Program, the African Union’s initiatives, and the EU’s RED. Additionally, international alliances like IEA Bioenergy TCP, GBA, and WEF play a significant role in harmonizing standards, sharing knowledge, and supporting emerging markets, contributing greatly to the successful deployment of biofuels. Infrastructure and capacity building, including investments in pipelines, transport, and biorefineries, along with skills development, are essential for ensuring long-term sustainability. Technologies such as AI, machine learning, and IoT enhance logistics, supply chain resilience, and predictive maintenance, thereby improving both economic and environmental efficiency. Furthermore, education and awareness campaigns, such as Brazil’s flex-fuel vehicle campaign and India’s ethanol blending mandate campaign, highlight the importance of social acceptance for widespread biofuel adoption.27

36. Conclusions

Ethanol’s century-long history reveals cycles of decline and resurgence, driven by oil price shocks, environmental imperatives, and technological innovation. Brazil’s unique trajectory — from early mandatory blending in 1931 to today’s flex-fuel dominance — demonstrates that ethanol can be integrated into a modern energy system at scale. The recent ethanol program in India, where in just a few years it has implemented a E20 in large country, producing and using ethanol with efficiency in more than 330 million cars, confirms that this path is open and feasible.

From a technical standpoint, ethanol’s high octane number, clean combustion, and compatibility with advanced engine technologies make it an enabler of high-efficiency ICEs and hybrid systems. From a climate perspective, ethanol offers proven life-cycle GHG reductions, especially when compared with gasoline and even in comparison with battery electric vehicles under certain conditions.

Ultimately, ethanol should not be seen as competing with electrification, but rather as a complementary and enduring pathway. Especially in regions with large existing vehicle fleets, long distances, and limited charging infrastructure — such as Latin America, Africa, and parts of Asia — ethanol offers an immediate, cost-effective, technically sound, and scalable contribution to the energy transition.

Acknowledgements

This study was supported by the Toyota Foundation. The authors would like to express their gratitude to Roberto Braun and the entire team for providing the necessary data and facilitating valuable discussions.

1 Torroba, A. and Chiara, A. (2024). Liquid Biofuels Atlas 2023-2024. IICA. https://repositorio.iica.int/server/api/core/bitstreams/62ee1218-39dc-4796-8dfb-d6d81e3109d7/content

2 Cantarella, H., Leal-Silva, J. F., Nogueira, L. A., Maciel Filho, R., Rossetto, R., Ekbom, T., Souza G. M. and Mueller-Langer, F. (2023). Biofuel technologies: lessons learned and pathways to decarbonization. Global Change Biology Bioenergy 15: 1190-1203. https://onlinelibrary.wiley.com/doi/full/10.1111/gcbb.13091

Biofuels as an immediate and effective solution for decarbonization of transportation – Factsheet. (2025). BIOEN Program.

https://bioenfapesp.org/biofuels-as-an-immediate-and-effective-solution-for-decarbonization-of-transportation-factsheet/

Cantarella, H., Souza, G. M., Nogueira, L. H., Maciel Filho, R., Paiva, G. C., Canabarro, N. I., Ortiz, P. S., Ekbom, T. and Silva, J. F. L. (2023). Assessment of successes and lessons learned for biofuels deployment – meta-analysis of existing studies. IEA Bioenergy. https://www.ieabioenergy.com/wp-content/uploads/2023/11/WP2-Report_13Nov2023.pdf

3 Delivering Sustainable Fuels Pathways to 2035. (2025). https://www.iea.org/reports/delivering-sustainable-fuels

https://cop30.br/en/news-about-cop30/brazil-pledges-to-quadruple-production-of-sustainable-fuels

Cantarella, H., Leal-Silva, J. F., Nogueira, L. A., Maciel Filho, R., Rossetto, R., Ekbom, T., Souza, G. M. and Mueller-Langer, F. (2023). Biofuel technologies: lessons learned and pathways to decarbonization. Global Change Biology Bioenergy 15: 1190-1203. https://onlinelibrary.wiley.com/doi/full/10.1111/gcbb.13091

Biofuels as an immediate and effective solution for decarbonization of transportation – Factsheet. (2025). BIOEN Program.

https://bioenfapesp.org/biofuels-as-an-immediate-and-effective-solution-for-decarbonization-of-transportation-factsheet/

Transport Biofuels – Renewables 2023. (2023). IEA. 2023. https://www.iea.org/reports/renewables-2023/transport-biofuels

4 Torroba, A. and Chiara, A. (2024). Liquid Biofuels Atlas 2023-2024. IICA. https://repositorio.iica.int/server/api/core/bitstreams/62ee1218-39dc-4796-8dfb-d6d81e3109d7/content

ISO Ethanol Yearbook 2023 (2023). International Sugar Organization – ISO.

https://www.isosugar.org/publication/341/iso-ethanol-yearbook-2023

India Sugar Production and Ethanol Market Outlook – March 2025 (2025). MEIR / Marex. https://meirindia.com/reports/MEIR-Marex-2024-25-India-Sugar-Production-and-Q-A-on-Sugar-Ethanol-Market-1-March-2025.pdf

Overview of Biofuels Policies and Markets Across the EU (2023). ePURE. https://www.epure.org/wp-content/uploads/2023/02/230227-DEF-REP-Overview-of-biofuels-policies-and-markets-across-the-EU-February-2023-1.pdf

Agricultural Production Statistics 2010–2023 (2024). FAO. https://openknowledge.fao.org/server/api/core/bitstreams/df90e6cf-4178-4361-97d4-5154a9213877/content

Transport Biofuels – Renewables 2023. (2023). IEA. https://www.iea.org/reports/renewables-2023/transport-biofuels.

5 Souza, G. M., Cantarella, H., Cassinelli, L. F., Nogueira, L. H., Rossetto, R. and Maciel Filho, R. (2023). Biofuels in emerging markets: potential for sustainable production and consumption. IEA Bioenergy Task 39.

Silva, J. F. L., Cantarella, H., Nogueira, L. A. H., Rosseto, R., Maciel Filho, R. and Souza, G. M. (2024). Biofuels in Emerging Markets of Africa and Asia. IEA Bioenergy.

Torroba, A. and Chiara, A. (2024). Liquid Biofuels Atlas 2023-2024. IICA. https://repositorio.iica.int/server/api/core/bitstreams/62ee1218-39dc-4796-8dfb-d6d81e3109d7/content

6 Anuário Estatístico Brasileiro do Petróleo, Gás Natural e Biocombustíveis 2024. (2024). ANP – Agência Nacional do Petróleo, Gás Natural e Biocombustíveis. https://www.gov.br/anp/pt-br/centrais-de-conteudo/publicacoes/anuario-estatistico/oil-natural-gas-and-biofuels-statistical-yearbook-2024

EU (2018), Directive (EU) 2018/2001. European Parliament, Official Journal of the European Union, vol. 2018, no. L 328, pp. 82–209, 2018

Hamelinck, C.; De Vita, S.; Smyth, T. & Scarlat, N. (2019). 2030 Transport decarbonisation options. p. 44, Ecofys, Farm Europe.

Watanabe, M. D. B.; Chagas, M. F.; Cavalett, O.; Guilhoto, J. J. M.; Griffin, W. M.; Cunha, M. P. & Bonomi, A. (2016). Hybrid input-output life cycle assessment of first- and second-generation ethanol production technologies in Brazil. Journal of Industrial Ecology, 20(4), 764–774.

Pereira, L., Cavalett, O., Bonomi, A., Zhang, Y., Warner, E. and Chum, H. L. (2019). Comparison of biofuel life-cycle GHG emissions assessment tools: the case studies of ethanol produced from sugarcane, corn, and wheat. Renewable & Sustainable Energy Reviews 110: 1–12. https://oa.mg/work/10.1016/j.rser.2019.04.043

Directive (EU) 2018/2001 of the European Parliament and of the Council on the promotion of the use of energy from renewable sources (RED II). (2018). EUROPEAN UNION (EU). https://energy.ec.europa.eu/topics/renewable-energy/bioenergy/biofuels_en

Manochio, C., Rodrigues, R. C., Ribeiro, M. P. and Maciel Filho, R. (2017). Ethanol from biomass: a comparative overview. Renewable and Sustainable Energy Reviews 80: 743–755. Ethanol from biomass: A comparative overview – ScienceDirect

Watanabe, M., Arruda, P. and Mello, L. V. (2016). Sugarcane for bioenergy production: an assessment of yield and sustainability. In: Santos, F. and Buckeridge, M. S., eds. Sugarcane-based biofuels and bioproducts. Hoboken: Wiley, p. 333–56. Sugarcane-based Biofuels and Bioproducts – Google Livros

Moreira, M. M. R., Seabra, J. E. A., Lynd, L. R., Arantes, S. M., Cunha, M. P. and Guilhoto, J. J. M. (2020). Socio-environmental and land-use impacts of double-cropped maize ethanol in Brazil. Nature Sustainability 3: 209–216. https://doi.org/10.1038/s41893-019-0456-2

Moreira, J. R., Romeiro, V., Fuss, S., Florian, K. and Pacca, S. (2016). BECCS potential in Brazil: achieving negative emissions in ethanol and electricity production based on sugar cane bagasse and other residues. Applied Energy, Amsterdam 179: 55-63. https://doi.org/10.1016/j.apenergy.2016.06.044

Chagas, M., Cavalett, O., Klein, B., Maciel-Filho, R. and Bonomi, A. (2016). Life cycle assessment of technologies for greenhouse gas emissions reduction in sugarcane biorefineries. Chemical Engineering Transactions 50: 421-426. https://doi.org/10.3303/CET1650071

Carbon accounting for sustainable biofuels. (2024). IEA. https://www.iea.org/reports/carbon-accounting-for-sustainable-biofuels

Comparison of Biofuel Life Cycle Assessment Tools. (2019). IEA Bioenergy Task 39. https://task39.ieabioenergy.com/wp-content/uploads/sites/37/2019/04/Task-39-GHS-models-Final-Report-Phase-1.pdf

7 Pelkmans, L. (2024). IEA Bioenergy: Countries’ Report – update 2024: implementation of bioenergy in the IEA bioenergy member countries. IEA Bioenergy. https://www.ieabioenergy.com/wp-content/uploads/2025/01/CountriesReport2024_final.pdf

8 Brazilian Energy Balance – Summary Report 2025: Reference Year 2024. (2025). EPE. https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-885/topico-767/BEN_Síntese_2025_EN.pdf

Balanço Energético Nacional 2025: ano base 2024 – Relatório Final. (2025). EPE. https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-885/topico-771/Relatório%20Final_BEN%202025.pdf

Análise de conjuntura dos biocombustíveis – ano base 2024, nota técnica EPE/DPG/SDB/2025/06. (2025). EPE. https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-904/NT-EPE-DPG-SDB-2025-06_Análise%20de%20Conjuntura_Ano%20base%202024.pdf

BNDES & CGEE (2025). Bioethanol: fast track to mobility decarbonisation, Banco Nacional de Desenvolvimento Econômico e Social, and Centro de Gestão de Estudos Estratégicos, Brasília (in print).

9 Canabarro, N. I., Silva-Ortiz, P., Nogueira, L. A. H., Cantarella, H., Maciel Filho, R. and Souza, G. M. (2023). Sustainability assessment of ethanol and biodiesel production in Argentina, Brazil, Colombia, and Guatemala. Renewable & Sustainable Energy Reviews: 171: 113019. https://doi.org/10.1016/j.rser.2022.113019

Pighinelli, A. L. M. T., Ramos, N. P. and Folegatti, M. I. S. Use of Renovacalc to evaluate the carbon intensity of combustible ethanol. (2021). In: CONGRESSO NACIONAL DE ENERGIA RENOVÁVEL – CONER, 6. Anais […]. Natal: UFRN, 2021. https://www.alice.cnptia.embrapa.br/alice/bitstream/doc/1133833/1/Pighinelli-Utilizacao-renovacalc-2021.pdf

10 Canabarro, N. I., Silva-Ortiz, P., Nogueira, L. A. H., Cantarella, H., Maciel Filho, R. and Souza, G. M. (2023). Sustainability assessment of ethanol and biodiesel production in Argentina, Brazil, Colombia, and Guatemala. Renewable & Sustainable Energy Reviews: 171: 113019. https://doi.org/10.1016/j.rser.2022.113019

Análise de conjuntura dos biocombustíveis – ano base 2024, nota técnica EPE/DPG/SDB/2025/06. (2025). EPE. https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-904/NT-EPE-DPG-SDB-2025-06_Análise%20de%20Conjuntura_Ano%20base%202024.pdf

11 Análise de conjuntura dos biocombustíveis – ano base 2024, nota técnica EPE/DPG/SDB/2025/06. (2025). EPE. https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-904/NT-EPE-DPG-SDB-2025-06_Análise%20de%20Conjuntura_Ano%20base%202024.pdf

Ramos, N. P., Mendes, N. C., Folegatti, M. I. S., Bayma, G., Novaes, R. M. L., Morandi, M. A. B., Pighinelli, A. L. M. T., Savioli, J. P. P. D. and Buffon, V. B. (2024). Regionalização de perfis agrícolas “típicos” da cana-de-açúcar para uso no RenovaBio. Embrapa Meio Ambiente. https://www.gov.br/anp/pt-br/assuntos/renovabio/arq/arquivos-estudos-relatorio-e-seminarios/sugarcane-agricultural-profiles-renovabio-2024.pdf.

Bordonal, R.O., Carvalho, J. L. N., Lal, R., Figueiredo, E. B., Oliveira, B. G. and La Scala Jr, N. (2018). Sustainability of sugarcane production in Brazil: a review. Agronomy for Sustainable Development: 38: 13. https://doi.org/10.1007/s13593-018-0490-x

Duarte, Y. C. N. and Sentelhas, P. C. (2020). Intercomparison and performance of maize crop models and their ensemble for yield simulations in Brazil. International Journal of Plant Production 14: 45–58. https://doi.org/10.1007/s42106-019-00073-5

12 Resultados do Projeto CAR 2021: áreas dedicadas à preservação da vegetação nativa nos imóveis rurais do Brasil. (2021). Embrapa Territorial. https://www.embrapa.br/car-2021/resultados

MapBiomas Brasil – Produtos: coleções anuais de mapas de cobertura e uso da terra. (2025). MapBiomas. https://brasil.mapbiomas.org/produtos/

13 Análise de conjuntura dos biocombustíveis – ano base 2024, nota técnica EPE/DPG/SDB/2025/06. (2025). EPE. https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-904/NT-EPE-DPG-SDB-2025-06_Análise%20de%20Conjuntura_Ano%20base%202024.pdf

14 Ahmed, S., Warne, T., Smith, E., Goemann, H., Linse, G., Greenwood, M., Kedziora, J., Sapp, M., Kraner, D., Roemer, K., Haggerty, J. H., Jarchow, M., Swanson, D., Poulter, B. and Stoy, P. C. (2021). Systematic review on effects of bioenergy from edible versus inedible feedstocks on food security. Science of Food 5: 9. https://doi.org/10.1038/s41538-021-00091-6

15 Observed changes associated to bioenergy in Brazil that contribute to food security are inproved energy access, improved, agricultural infrastructure, agricultural modernization, improved soil quality and improved purchasing power. One of the most important contributers to food insecurity is poverty. So I will talk about social development.

16 Moraes, M. A. F. D., Oliveira, F. C. R. and Diaz-Chavez, R. A. (2015). Socio-economic impacts of Brazilian sugarcane industry. Environmental Development 16: 31–43. https://doi.org/10.1016/j.envdev.2015.06.010

Moraes, M. A. F. D., Bacchi, M. R. P. and Caldarelli, C. E. (2016). Accelerated growth of the sugarcane, sugar, and ethanol sectors in Brazil (2000–2008): effects on municipal gross domestic product per capita in the south-central region. Biomass Bioenergy 91: 116–25. https://doi.org/10.1016/j.biombioe.2016.05.004

UNICA Data: indicadores da produção sucroenergética brasileira. (2025). União da Indústria da Cana-de-Açúcar. https://unicadata.com.br/listagem.php?idMn=158

17 Ambrosano, E. J., Trivelin, P. C. O., Cantarella, H., Ambrosano, G. M. B., Schammass, E. A., Muraoka, T. and Rossi, F. (2011). 15N-labeled nitrogen from green manure and ammonium sulfate utilization by the sugarcane ratoon. Scientia Agricola 68: 361–368. https://doi.org/10.1590/S0103-90162011000300014

Ball-Coelho, B., Sampaio, E. V. S. B., Tiessen, H. and Stewart, J. W. B. (1992). Root dynamics in plant and ratoon crops of sugar cane. Plant Soil 142: 297–305. https://doi.org/10.1007/BF00010975

Barbosa, L. C., Magalhães, P. S. G., Bordonal, R. O., Cherubin, M. R., Castioni, G. A., Rossi Neto, J., Franco, H. C. J. and Carvalho, J. L. N. (2021). Untrafficked furrowed seedbed sustains soil physical quality in sugarcane mechanized fields. European Journal of Soil Science 72: 2150–2164. https://doi.org/10.1111/ejss.13107.

Bordonal, R.O., Carvalho, J. L. N., Lal, R., Figueiredo, E. B., Oliveira, B. G. and La Scala Jr, N. (2018). Sustainability of sugarcane production in Brazil – a review. Agronomy for Sustainable Development 38: 1–23. https://doi.org/10.1007/s13593-018-0490-x

Borges, C. D., Carvalho, J. L. N., Kolln, O. T., Sanches, G. M., Silva, M. J., Castro, S. G. Q., Castro, S. A. Q., Sousa, L. L., Oliveira, J. V. C., Cantarella, H., Vargas, V. P., Tsai, S. M. and Franco, H. C. J. (2019). Can alternative N-fertilization methods influence GHG emissions and biomass production in sugarcane fields? Biomass and Bioenergy 120: 21–27. https://doi.org/10.1016/j.biombioe. 2018.10.017

Cantarella, H., Trivelin, P. C. O., Contin, T. L. M., Dias, F. L. F., Rossetto, R., Marcelino, R., Coimbra, R. B. and Quaggio, J. A. (2008). Ammonia volatilisation from urease inhibitor-treated urea applied to sugarcane trash blankets. Scientia Agricola 65: 397–401. https://doi.org/10.1590/S0103-90162008000400011

Cantarella, H., Cerri, C. E. P., Carvalho, J. L. N. and Magalhaes, P. S. G. (2013). Editorial: how much sugarcane trash should be left on the soil. Scientia Agricola 70: 1–2. https://doi.org/10.1590/S0103-90162013000500001

Cardoso, E. J. B. N., Vasconcellos, R. L. F., Bini, D., Miyauchi, M. Y. H., Santos, C. A., Alves, P. R. L., Paula, A. M., Nakatani, A. S., Pereira, J. M. and Nogueira, M. A. (2013). Soil health: looking for suitable indicators. What should be considered to assess the effects of use and management on soil health? Scientia Agricola 70: 274-289. https://doi.org/10.1590/S0103-90162013000400009

Cardozo, N. P., Bordonal, R. O. and La Scala, N. (2016) Greenhouse gas emission estimate in sugarcane irrigation in Brazil: is it possible to reduce it, and still increase crop yield? Journal of Cleaner Production 112: 3988-3997. https://doi.org/10.1016/j.jclepro.2015.09.040

Carmo, J. B., Filoso, S., Zotelli, L. C., Sousa Neto, E. R., Pitombo, L. M., Duarte-Neto, P. J., Vargas, V. P., Andrade, C. A., Gava, G. J. C., Rossetto, R., Cantarella, H., Neto, A. E. and Martinelli, L. A. (2013). Infield greenhouse gas emissions from sugarcane soils in Brazil: effects from synthetic and organic fertilizer application and crop trash accumulation. Global Change Biology Bioenergy: 5: 267–280. https://doi.org/10.1111/j.1757-1707.2012.01199.x

Carvalho, J. L. N., Hudiburg, T. W., Franco, H. C. J. and DeLucia, E. H. (2017). Contribution of above- and belowground bioenergy crop residues to soil carbon. GCB Bioenergy 9: 1333–1343. https://doi.org/10.1111/gcbb.12411

Carvalho, J. L. N., Nogueirol, R. C., Menandro, L. M. S., Bordonal, R. O., Borges, C. D., Cantarella, H. and Franco, H. C. J. (2017). Agronomic and environmental implications of sugarcane straw removal: a major review. GCB Bioenergy 9: 1181–1195. https://doi.org/10.1111/gcbb.12410

Cherubin, M. R., Franco, A. L. C., Cerri, C. E. P., Oliveira, D. M. S., Davies, C. A. and Cerri, C. C. (2015). Sugarcane expansion in Brazilian tropical soils-effects of land use change on soil chemical attributes. Agriculture Ecosystems & Environment 211: 173–184. https://doi.org/10.1016/j.agee.2015.06.006

Lutz, S., Bodenhausen, N., Hess, J., Valzano-Held, A., Waelchli, J., Deslandes-Hérold, G., Schlaeppi, K. and van der Heijden, M. G. A. (2024). Soil microbiome indicators can predict crop growth response to large-scale inoculation with arbuscular mycorrhizal fungi. Nature Microbiology 9: 1630. https://doi.org/10.1038/s41564-023-01577-7

Moraes, E. R., Mageste, J. G., Lana, R. M. Q., Torres, J. L. R., Domingues, L. A. D. S., Lemes, E. M. and Lima, L. C. (2019). Sugarcane root development and yield under different soil tillage practices. Revista Brasileira de Ciência do Solo 43: e0180090. https://doi.org/10.1590/18069657rbcs20180090

Otto, R., Silva, A. P., Franco, H. C. J., Oliveira, E. C. A. and Trivelin, P. C. O. (2011). High soil penetration resistance reduces sugar cane root system development. Soil and Tillage Research 117: 201–210. https://doi.org/10.1016/j.still.2011.10.005.

Pereira, W., Oliveira, R. P., Pereira, A., Sousa, J. S., Schultz, N., Urquiaga, S. and Reis, V. M. (2021). Nitrogen acquisition and 15N fertiliser recovery efficiency of sugarcane cultivar RB92579 inoculated with five diazotrophs. Nutrient Cycling in Agroecosystems 119: 37–50. https://doi.org/10.1007/s10705-020-10100-x

Perin, V., Sentelhas, P. C., Dias, H. B. and Santos, E. A. (2019). Sugarcane irrigation potential in Northwestern São Paulo, Brazil, by integrating Agrometeorological and GIS tools. Agricultural Water Management 220: 50–58. https://doi.org/10.1016/j.agwat.2019.04.012

del Pino, A., Casanova, O., Jorge, H. and Takata, V. H. (2022). Vinasse for sugarcane crop nutrition accumulation and efficiency in the use of nutrients. Australian Journal of Crop Science 16: 1107–1116. https://doi.org/10.21475/ajcs.22.16.09.p3617

Prado, R. M., Caione, G. and Campos, C. N. S. (2013). Filter cake and vinasse as fertilizers contributing to conservation agriculture. Applied and Environmental Soil Science, 1–8. http://dx.doi.org/10.1155/2013/581984

Pryor, S. W., Smithers, J., Lyne, P. and van Antwerpen, R. (2017). Impact of agricultural practices on energy use and greenhouse gas emissions for South African sugarcane production. Journal of Cleaner Production 141: 137–145. https://doi.org/10.1016/j.jclepro.2016.09.069

Ramos, L. A., Lana, R. M. Q., Korndorfer, G. H. and Silva, A. A. (2017). Effect of organo-mineral fertilizer and poultry litter waste on sugarcane yield and some plant and soil chemical property. African Journal of Agriculture Research 12: 20–27. https://doi.org/10.5897/AJAR2016.11024

Raposo Junior, J. L., Gomes Neto, J. A. and Sacramento, L. V. S. (2013). Evaluation of different foliar fertilizers on the crop production of sugarcane. Journal of Plant Nutrition 36: 459–469. https://doi.org/10.1080/01904167.2012.748066

Reis, G. V., Siebeneichler, S. C., Lazzaretti, B., Sousa, A. S., Resplandes, M. A., Marques, R. B., Sousa, A. P., Santos, M. F. R., Rosa, L. P. and Oliveira, M. (2019). Growth response of pre-sprouted seedlings of sugarcane in the presence of the bacterium Herbarspirillum frisingense. International Journal of Environment, Agriculture and Biotechnology 4: 1387–1391. https://doi.org/10.22161/ijeab.45.15

Ribeiro, C. H. and Cunha, M. P. (2022). The economic and environmental impacts of Brazilian National Biofuel Policy. Biofuels, Bioproducts and Biorefining 16: 413– 434. https://doi.org/10.1002/BBB.2326

Rossato, O. B., Foltran, R., Crusciol, C. A. C., Martello, J. M., Rossetto, R. and McCray, J. M. (2017). Soil fertility, ratoon sugarcane yield, and post-harvest residues as affected by surface application of lime and gypsum in southeastern Brazil. Bioscience Journal 33: 276–287. https://doi.org/10.14393/BJ-v33n2-32755.

Rossetto, R., Dias, F. L. F., Vitti, A. C. and Cantarella, H. (2010). Fertility maintenance and soil recovery in sugarcane crops. In: Cortez, L. A. B., ed. Sugarcane bioethanol R&D for productivity and sustainability. São Paulo: Blucher, p. 381–403. https://doi.org/10.5151/BlucherOA-Sugarcane

Rossetto, R., Ramos, N. P., Pires, R. C. M., Xavier, M. A., Cantarella, H. and Landell, M. G. A. (2022). Sustainability in sugarcane supply chain in Brazil: issues and way forward. Sugar Tech 24: 941–966. https://doi.org/10.1007/s12355-022-01170-y

Sales, F. R., Silva, A. O., Sales, L. R., Rodrigues, T. L., Moreira, F. M. S. and Carneiro, M. A. C. (2021). Native arbuscular mycorrhizal fungi exhibit biotechnological potential in improvement of soil biochemical quality and in increasing yield in sugarcane cultivars. Sugar Tech 23: 998–1008. https://doi.org/10.1007/s12355-021-01016-z

Santos, L. C., Coelho, R. D., Barbosa, F. S., Leal, D. P. V., Fraga Júnior, E. F., Barros, T. H. S., Lizcano, J. V. and Ribeiro, N. L. (2019). Influence of deficit irrigation on accumulation and partitioning of sugarcane biomass under drip irrigation in commercial varieties. Agricultural Water Management 221: 322–333. https://doi.org/10.1016/j.agwat.2019.05.013

Silva, P. C. G., Tiritan, C. S., Echer, F. R., Cordeiro, C. F. S., Rebonatti, M. D. and Santos, C. H. (2020). No-tillage and crop rotation increase crop yields and nitrogen stocks in sandy soils under agroclimatic risk. Field Crops Research 258: 107947. https://doi.org/10.1016/j.fcr.2020.107947

Simanjuntak, B. H. and Lengkong, C. P. R. (2017). The soil microbiological properties assessment due sugarcane vinasse application. Journal of Biological and Environment Sciences 11: 251–260.

Soares, G., Souza, Z.M., Cooper, M. and Tormena, C.A. (2015). Controlled traffic and soil physical quality of an oxisol under sugarcane cultivation. Scientia Agricola 72: 270–277. https://doi.org/10.1590/0103-9016-2014-0078.

Tayyab, M., Yang, Z., Zhang, C., Islam, W., Lin, W. and Zhang, H. (2021). Sugarcane monoculture drives microbial community composition, activity and abundance of agricultural-related microorganisms. Environmental Science and Pollution Research 28: 48080–48096. https://doi.org/10.1007/s11356-021-14033-y

van Antwerpen, R., van Heerden, P. D. R., Keeping, M. G., Titshall, L. W., Jumman, A., Tweddle, P. B., van Antwerpen, T., Ramouthar, P. V. and Campbell, P. L. (2022). A review of field management practices impacting root health in sugarcane. Advance in Agronomy 173: 79-162. https://doi.org/10.1016/bs.agron.2022.02.002

van Antwerpen, R. and Stranack, R. A. (2021). Soil conservation practices used in the South African sugarcane industry over the last 80 years – a review. Proceedings of the South African Sugar Technologists’ Association 93: 172-186.

18 Ambrosano, E. J., Trivelin, P. C. O., Cantarella, H., Ambrosano, G. M. B., Schammass, E. A., Muraoka, T. and Rossi, F. (2011). 15N-labeled nitrogen from green manure and ammonium sulfate utilization by the sugarcane ratoon. Scientia Agricola 68: 361–368. https://doi.org/10.1590/S0103-90162011000300014

Ball-Coelho, B., Sampaio, E. V. S. B., Tiessen, H. and Stewart, J. W. B. (1992). Root dynamics in plant and ratoon crops of sugar cane. Plant Soil 142: 297–305. https://doi.org/10.1007/BF00010975

Barbosa, L. C., Magalhães, P. S. G., Bordonal, R. O., Cherubin, M. R., Castioni, G. A., Rossi Neto, J., Franco, H. C. J. and Carvalho, J. L. N. (2021). Untrafficked furrowed seedbed sustains soil physical quality in sugarcane mechanized fields. European Journal of Soil Science 72: 2150–2164. https://doi.org/10.1111/ejss.13107.

Bordonal, R. O., Carvalho, J. L. N., Lal, R., Figueiredo, E. B., Oliveira, B. G. and La Scala Jr, N. (2018). Sustainability of sugarcane production in Brazil: a review. Agronomy for Sustainable Development: 38: 13.

https://link.springer.com/content/pdf/10.1007/s13593-018-0490-x.pdf

Borges, C. D., Carvalho, J. L. N., Kolln, O. T., Sanches, G. M., Silva, M. J., Castro, S. G. Q., Castro, S. A. Q., Sousa, L. L., Oliveira, J. V. C., Cantarella, H., Vargas, V. P., Tsai, S. M. and Franco, H. C. J. (2019). Can alternative N-fertilization methods influence GHG emissions and biomass production in sugarcane fields? Biomass and Bioenergy 120: 21–27. https://doi.org/10.1016/j.biombioe. 2018.10.017

Cantarella, H., Trivelin, P. C. O., Contin, T. L. M., Dias, F. L. F., Rossetto, R., Marcelino, R., Coimbra, R. B. and Quaggio, J. A. (2008). Ammonia volatilisation from urease inhibitor-treated urea applied to sugarcane trash blankets. Scientia Agricola 65: 397–401. https://doi.org/10.1590/S0103-90162008000400011

Cantarella, H., Cerri, C. E. P., Carvalho, J. L. N. and Magalhaes, P. S. G. (2013). Editorial: how much sugarcane trash should be left on the soil. Scientia Agricola 70: 1–2.

Cardoso, E. J. B. N., Vasconcellos, R. L. F., Bini, D., Miyauchi, M. Y. H., Santos, C. A., Alves, P. R. L., Paula, A. M., Nakatani, A. S., Pereira, J. M. and Nogueira, M. A. (2013). Soil health: looking for suitable indicators. What should be considered to assess the effects of use and management on soil health? Scientia Agricola 70: 274-289. https://doi.org/10.1590/S0103-90162013000400009

Cardozo, N. P., Bordonal, R. O. and La Scala, N. (2016) Greenhouse gas emission estimate in sugarcane irrigation in Brazil: is it possible to reduce it, and still increase crop yield? Journal of Cleaner Production 112: 3988-3997. https://doi.org/10.1016/j.jclepro.2015.09.040

Carmo, J. B., Filoso, S., Zotelli, L. C., Sousa Neto, E. R., Pitombo, L. M., Duarte-Neto, P. J., Vargas, V. P., Andrade, C. A., Gava, G. J. C., Rossetto, R., Cantarella, H., Neto, A. E. and Martinelli, L. A. (2013). Infield greenhouse gas emissions from sugarcane soils in Brazil: effects from synthetic and organic fertilizer application and crop trash accumulation. Global Change Biology Bioenergy 5: 267–280. https://doi.org/10.1111/j.1757-1707.2012.01199.x

Carvalho, J. L. N., Hudiburg, T. W., Franco, H. C. J. and DeLucia, E. H. (2017). Contribution of above- and belowground bioenergy crop residues to soil carbon. GCB Bioenergy 9: 1333–1343. https://doi.org/10.1111/gcbb.12411

Carvalho, J. L. N., Nogueirol, R. C., Menandro, L. M. S., Bordonal, R. O., Borges, C. D., Cantarella, H. and Franco, H. C. J. (2017). Agronomic and environmental implications of sugarcane straw removal: a major review. GCB Bioenergy 9: 1181–1195. https://doi.org/10.1111/gcbb.12410

Cherubin, M. R., Franco, A. L. C., Cerri, C. E. P., Oliveira, D. M. S., Davies, C. A. and Cerri, C. C. (2015). Sugarcane expansion in Brazilian tropical soils – effects of land use change on soil chemical attributes. Agriculture, Ecosystems and Environment 211: 173–184. https://doi.org/10.1016/j.agee.2015.06.006

Lutz, S., Bodenhausen, N., Hess, J., Valzano-Held, A., Waelchli, J., Deslandes-Hérold, G., Schlaeppi, K. and van der Heijden, M. G. A. (2024). Soil microbiome indicators can predict crop growth response to large-scale inoculation with arbuscular mycorrhizal fungi. Nature Microbiology 9: 1630. https://doi.org/10.1038/s41564-023-01577-7

Moraes, E. R., Mageste, J. G., Lana, R. M. Q., Torres, J. L. R., Domingues, L. A. D. S., Lemes, E. M. and Lima, L. C. (2019). Sugarcane root development and yield under different soil tillage practices. Revista Brasileira de Ciência do Solo 43: e0180090. https://doi.org/10.1590/18069657rbcs20180090

Otto, R., Silva, A. P., Franco, H. C. J., Oliveira, E. C. A. and Trivelin, P. C. O. (2011). High soil penetration resistance reduces sugar cane root system development. Soil and Tillage Research 117: 201–210. https://doi.org/10.1016/j.still.2011.10.005

Pereira, W., Oliveira, R. P., Pereira, A., Sousa, J. S., Schultz, N., Urquiaga, S. and Reis, V. M. (2021). Nitrogen acquisition and 15N fertiliser recovery efficiency of sugarcane cultivar RB92579 inoculated with five diazotrophs. Nutrient Cycling in Agroecosystems 119: 37–50. https://doi.org/10.1007/s10705-020-10100-x

Perin, V., Sentelhas, P. C., Dias, H. B. and Santos, E. A. (2019). Sugarcane irrigation potential in Northwestern São Paulo, Brazil, by integrating Agrometeorological and GIS tools. Agricultural Water Management 220: 50–58. https://doi.org/10.1016/j.agwat.2019.04.012

del Pino, A., Casanova, O., Jorge, H. and Takata, V. H. (2022). Vinasse for sugarcane crop nutrition accumulation and efficiency in the use of nutrients. Australian Journal of Crop Science 16: 1107–1116. https://doi.org/10.21475/ajcs.22.16.09.p3617

Prado, R. M., Caione, G. and Campos, C. N. S. (2013). Filter cake and vinasse as fertilizers contributing to conservation agriculture. Applied and Environmental Soil Science, 1–8. http://dx.doi.org/10.1155/2013/581984

Pryor, S. W., Smithers, J., Lyne, P. and van Antwerpen, R. (2017). Impact of agricultural practices on energy use and greenhouse gas emissions for South African sugarcane production. Journal of Cleaner Production 141: 137–145. https://doi.org/10.1016/j.jclepro.2016.09.069

Ramos, L. A., Lana, R. M. Q., Korndorfer, G. H. and Silva, A. A. (2017). Effect of organo-mineral fertilizer and poultry litter waste on sugarcane yield and some plant and soil chemical property. African Journal of Agriculture Research 12: 20–27. https://doi.org/10.5897/AJAR2016.11024

Raposo Junior, J. L., Gomes Neto, J. A. and Sacramento, L. V. S. (2013). Evaluation of different foliar fertilizers on the crop production of sugarcane. Journal of Plant Nutrition 36: 459–469. https://doi.org/10.1080/01904167.2012.748066

Reis, G. V., Siebeneichler, S. C., Lazzaretti, B., Sousa, A. S., Resplandes, M. A., Marques, R. B., Sousa, A. P., Santos, M. F. R., Rosa, L. P. and Oliveira, M. (2019). Growth response of pre-sprouted seedlings of sugarcane in the presence of the bacterium Herbarspirillum frisingense. International Journal of Environment, Agriculture and Biotechnology 4: 1387–1391. https://doi.org/10.22161/ijeab.45.15

Ribeiro, C. H. and Cunha, M. P. (2022). The economic and environ mental impacts of Brazilian National Biofuel Policy. Biofuels, Bioproducts and Biorefining 16: 413– 434. https://doi.org/10.1002/BBB.2326

Rossato, O. B., Foltran, R., Crusciol, C. A. C., Martello, J. M., Rossetto, R. and McCray, J. M. (2017). Soil fertility, ratoon sugarcane yield, and post-harvest residues as affected by surface application of lime and gypsum in southeastern Brazil. Bioscience Journal 33: 276–287. https://doi.org/10.14393/BJ-v33n2-32755.

Rossetto, R., Dias, F. L. F., Vitti, A. C. and Cantarella, H. (2010). Fertility maintenance and soil recovery in sugarcane crops. In: Cortez, L. A. B., ed. Sugarcane bioethanol R&D for productivity and sustainability. São Paulo: Blucher, p. 381–403. https://doi.org/10.5151/BlucherOA-Sugarcane

Rossetto, R., Ramos, N. P., Pires, R. C. M., Xavier, M. A., Cantarella, H. and Landell, M. G. A. (2022). Sustainability in sugarcane supply chain in Brazil: issues and way forward. Sugar Tech 24: 941–966. https://doi.org/10.1007/s12355-022-01170-y

Sales, F. R., Silva, A. O., Sales, L. R., Rodrigues, T. L., Moreira, F. M. S. and Carneiro, M. A. C. (2021). Native arbuscular mycorrhizal fungi exhibit biotechnological potential in improvement of soil biochemical quality and in increasing yield in sugarcane cultivars. Sugar Tech 23: 998–1008. https://doi.org/10.1007/s12355-021-01016-z

Santos, L. C., Coelho, R. D., Barbosa, F. S., Leal, D. P. V., Fraga Júnior, E. F., Barros, T. H. S., Lizcano, J. V. and Ribeiro, N. L. (2019). Influence of deficit irrigation on accumulation and partitioning of sugarcane biomass under drip irrigation in commercial varieties. Agricultural Water Management 221: 322–333. https://doi.org/10.1016/j.agwat.2019.05.013

Silva, P. C. G., Tiritan, C. S., Echer, F. R., Cordeiro, C. F. S., Rebonatti, M. D. and Santos, C. H. (2020). No-tillage and crop rotation increase crop yields and nitrogen stocks in sandy soils under agroclimatic risk. Field Crops Research 258: 107947. https://doi.org/10.1016/j.fcr.2020.107947

Simanjuntak, B. H. and Lengkong, C. P. R. (2017). The soil microbiological properties assessment due sugarcane vinasse application. Journal of Biological and Environment Sciences 11: 251–260.

Soares, G., Souza, Z.M., Cooper, M. and Tormena, C.A. (2015). Controlled traffic and soil physical quality of an oxisol under sugarcane cultivation. Scientia Agricola 72: 270–277. https://doi.org/10.1590/0103-9016-2014-0078.

Tayyab, M., Yang, Z., Zhang, C., Islam, W., Lin, W. and Zhang, H. (2021). Sugarcane monoculture drives microbial community composition, activity and abundance of agricultural-related microorganisms. Environmental Science and Pollution Research 28: 48080–48096. https://doi.org/10.1007/s11356-021-14033-y

van Antwerpen, R., van Heerden, P. D. R., Keeping, M. G., Titshall, L. W., Jumman, A., Tweddle, P. B., van Antwerpen, T., Ramouthar, P. V. and Campbell, P. L. (2022). A review of field management practices impacting root health in sugarcane. Advance in Agronomy 173: 79-162. https://doi.org/10.1016/bs.agron.2022.02.002

van Antwerpen, R. and Stranack, R. A. (2021). Soil conservation practices used in the South African sugarcane industry over the last 80 years – a review. Proceedings of the South African Sugar Technologists’ Association 93: 172-186.

19 Gurgel, A. C., Seabra, J. E. A., Arantes, S. M., Moreira, M. M. R., Lynd, L. R. and Galindo, R. (2024). Contribution of double-cropped maize ethanol in Brazil to sustainable development. Nature Sustainability 7: 1429-1440. https://doi.org/10.1038/s41893-024-01424-5

Silva, J. F. L., Nogueira, L. A. H., Cantarella, H., Rossetto, R., Maciel Filho, R. and Souza, G. M. (2025). Meta-analysis of biofuels in emerging markets of Africa and Asia: green house gas savings and economic feasibility. Renewable and Sustainable Energy Reviews 213: 115465. https://doi.org/10.1016/j.rser.2025.115465

20 Guarenghi, M. M., Garofalo, D. F. T., Seabra, J. E. A., Moreira, M. M. R., Novaes, R. M. L., Ramos, N. P., Nogueira, S. F. and Andrade, C. A. (2023). Land use change net removals associated with sugarcane in Brazil. Land 12: 584. https://doi.org/10.3390/land12030584

21 Souza, G. M., Cantarella, H., Cassinelli, L. F., Nogueira, L. H., Rossetto, R. and Maciel Filho, R. (2023). Biofuels in emerging markets: potential for sustainable production and consumption. IEA Bioenergy Task 39.

Talk Glaucia ExCo Workshop Emerging Markets 230523 v2

Silva, J. F. L., Cantarella, H., Nogueira, L. A. H., Rosseto, R., Maciel Filho, R. and Souza, G. M. (2024). Biofuels in Emerging Markets of Africa and Asia. IEA Bioenergy. Emerging-Markets-Policy-Brief-pb2_v06.pdf

22 Souza, G. M., Cantarella, H., Cassinelli, L. F., Nogueira, L. H., Rossetto, R. and Maciel Filho, R. (2023). Biofuels in emerging markets: potential for sustainable production and consumption. IEA Bioenergy Task 39.

Talk Glaucia ExCo Workshop Emerging Markets 230523 v2

Silva, J. F. L., Cantarella, H., Nogueira, L. A. H., Rosseto, R., Maciel Filho, R. and Souza, G. M. (2024). Biofuels in Emerging Markets of Africa and Asia. IEA Bioenergy. Emerging-Markets-Policy-Brief-pb2_v06.pdf

23 ANP (2024), Pereira et al. (2019), EU (2018), Hamelinck et al. (2019), Moreira et al. (2020), Manochio et al., (2017), and Watanabe et al. (2016).

24 IEA Bioenergy Country Report, 2024

25 Gauto, M. A., Carazzolle, M. F., Rodrigues, M. E.P., Abreu, R. S., Pereira, T. C., Pereira, G. A. G. (2023). Hybrid vigor: Why hybrids with sustainable biofuels are better than pure electric vehicles. Energy for Sustainable Development 101261

26 Raman, S., Kumar, A., Singh, R., Sharma, A., Kumar, R., Singh, A. K., Kumar, V., Singh, D., Kumar, N., Singh, S., Kumar, M. and Singh, P. (2025). Analyzing the contributions of biofuels, biomass, and bioenergy to sustainable development goals. iScience 28: 112157. https://doi.org/10.1016/j.isci.2025.112157

27 Raman, S., Kumar, A., Singh, R., Sharma, A., Kumar, R., Singh, A. K., Kumar, V., Singh, D., Kumar, N., Singh, S., Kumar, M. and Singh, P. (2025). Analyzing the contributions of biofuels, biomass, and bioenergy to sustainable development goals. iScience 28: 112157. https://doi.org/10.1016/j.isci.2025.112157

PROGRAMAÇÃO

Manhã – 8h30 às 12h00

8h30 – 9h00 – Abertura

9h00 – 9h20: Coleções bacterianas para produção de polihidroxialcanoatos (S2B – J. Gregório C. Gomez)

9h20 – 9h40 : Oportunidades para produção de polihidroxialcanoatos no Brasil (Bioreset – Fernando Piovesana).

9h40 – 10h00 – Demanda por bioplásticos na indústria de cosméticos (Boticário – Francielle Saorin).

10h00-10h20 – Bioplásticos BASF (BASF – Thiago B. Spedo)

10h20 – 11h20 – Roda de conversas.

11h20 – 12h20 – Visita ao S2B – INOVA – USP.

Tarde – 14h00 às 17h00

14h00 – 14h20 – Produção de ácido polilático (PLA) no Brasil (ERT Bioplásticos)

14h20 – 14h40 – Polietileno verde – desafios e oportunidades (Braskem – Alex R. C. Duarte)

14h40 – 15h00 – PDC um substituto ao ácido tereftálico? (S2B – Igor Cesarino).

15h00 – 15h20 – Oportunidades para PETase (S2B – Flávia V. Winck).

15h20 – 15h40 – Palestra aguardando confirmação

15h40 – 16h40 – Roda de conversas.

16h40 – 17h00 – Encerramento.

Important information:

- The student must be a member of SBE and present his(er) work at the event.

- The amount of resources allocated to support students is limited, and requests will be considered on a first-come, first-served basis.

- The student must register for the event and contact SBE (sbe.bioenergy@gmail.com), attaching a copy of his(er) work and proof of enrollment in an Undergrad or Graduate Program.

- Supported students will receive a voucher to be used in the event’s registration system.

- SBE support is exclusively for the registration until July 31, 2024 (early registration).

We look forward to seeing you soon and wish you success in your bioenergy endeavors.

Sincerely,

Rafael V. Ribeiro

President of SBE